Features and Advantages :

1 .Welded structure by thick profiled steel stabilized under high temperature, ensures minimum distortion, excellent rigidity and powerful strength.

2. Japanese YAKSAWA servo motor makes the machine stable running with low noise, high speed and high accuracy.

3. Italy HSD spindle makes machine with high precision, long service time and stable movement.

4. Configured with carousel tool magazine of 12 tools, the machine can change tools speedy and freely.

5. Auto tool sensor enables the machine compensate the tolerance of the tool length.

6. High power suction vacuum pump, air-cooling, water-cooling or becker pump.

7. Taiwan SYNTEC control system, separated keyboard control, color LCD display, can alter the parameters and automatically change the tool .

8. Strong dust collector ensures site cleanliness during the machine operation.

9. Automatic lubricating system, one touch can finish periodic maintenance easily.

Applications :

1. Furnitures: kitchen cabinets, closets, entertainment centers, mdf doors.

2. Woodworking: voice box, game cabinets, computer tables, sewing machines table, instruments.

3. Panel Processing: insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti bate board, epoxy resin, ABS, PP, PE and other carbon mixed compounds.

4. Decorations: acrylic, PVC, MDF, artificial stone, organic glass, plastic and soft metals such as copper, aluminum.

Parameter:

Table size: | 1200mm*1200mm |

Spindle power: | 3.2KW water cooling spindle(Other power for optional) |

Working voltage: | AC380V or 220V /50Hz or 60HZ |

Working precision: | About 0.1mm |

Table structure | Aluminum working table with T slot |

Transmission | Taiwan HIWIN square guide rail, TBI Ball screw |

Motor and driver | Leadshine stepper motor and driver |

Spindle rotating speed: | 24000 revolution/min |

Max speed of working: | 25000mm/min |

Feeding height | 200mm(option) |

The diameter of rotary | 150mm |

The engraving instruction | G code |

Controller | Weihong controller/DSP/Mach 3 |

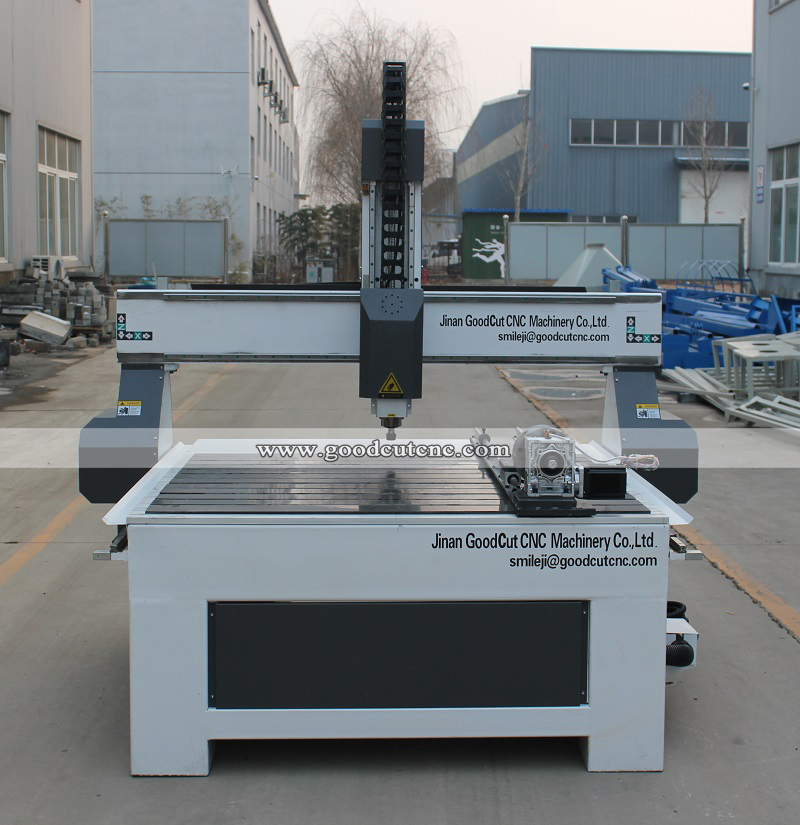

1. Welded frame, solidity and stable.

2. Adopt Hiwin square rail guides and imported TBI ball screw to ensure more stable

movement and high accuracy.

3. T-slot PVC table with Aluminum profile decorative appearance beautiful design.

4. Advanced water cooling brush-less spindle ,low noise ,long time mass processing.

5. NC studio controller/DSP/Mach 3 controller

6. Compatible with kinds of software such as TYPE3,Artcam,etc.

Detailed parts:

Samples :

What Is A CNC Wood Router?

A CNC wood router is an automatic computer-controlled machine tool for smart 2D, 2.5D, and 3D cutting, milling, carving, drilling, and grooving on popular woodworking plans, including wood arts & crafts, signs making, cabinets making, door making, gifts, modeling, decorations, wardrobe, and more furniture making projects & ideas.

Such a machine tool kit consists of bed frame, spindles, vacuum table or T-slot table, controller, operating system, software, gantry, driver, motor, vacuum pump, guide rail, pinion, rack, ball screw, collet, limit switch, power supply, and some additional parts & accessories.

How Does A Wood CNC Machine Work?

A wood CNC machine uses computer signals as instructions to control the movement, timing, logic and other functions through the computer, so as to drive the spindle and bits to complete woodworking automation.

Unlike handheld, palm, plunge, plunge base, and fixed base routers, the functional software of a CNC wood router is CAD/CAM. CAD software allows users to create the designs they wish to work on a woodworking CNC machine. After completing this design, the CAM software will convert the design into a tool path code that the wood CNC machine can understand. Then, the computer converts this code into a signal that controls the movement of the drive system of the machine. The drive system includes a spindle, which is the part that saves the actual machine position. The spindle rotates 8,000 to 50,000 times per minute to cut the material. In short, the user creates a design and uses the software to make instructions for the machine.

3 axis table kit cuts along three axes at the same time: X-axis, Y-axis and Z-axis. X axis makes the router bit move from front to back, Y axis makes it move from left to right, and Z axis makes it move up and down. They are used to cut 2D flat woodworking projects.

Compared with 3 axis, 5 axis machine tools can cut along two additional axes. These automatic computer-controlled machine tools can cut five sides of a piece of material at the same time, thereby expanding the capabilities and flexibility of operators. Unlike their 3-axis counterparts, these computer-controlled 5 axis machine tools are usually used to cut large 3D woodworking projects. In addition, 5 axis table kits have a higher gantry and a longer X-axis, which allows them to cut larger woodworking projects. However, if the gantry is higher and the X-axis is longer, the accuracy and stability will be worse. For proper quality control, the height of the gantry and the length of the X-axis should be limited as much as possible. Although computer-controlled woodworking routers look like simple power tools, they are highly complex technologies and require a certain amount of expertise to operate. 5 axis CNC wood milling machines tend to be more expensive than traditional 3 axis CNC wood routers, but ultimately provide high quality, greater flexibility, allowing users to use their designs more creatively.